This industry has been facing new and unprecedented challenges. To meet the increasing demand, companies are having to do more with less. This means that they are using fewer employees and tighter budgets. How can the industry keep up with these unprecedented times?

To keep up with the pace of the industry, it’s no surprise that oil and gas companies are turning to AR and VR to help create a more efficient workflow. By using immersive technologies to revamp their work processes, oil companies are finding major cost savings that help their businesses soar.

How AR/VR can Benefit the Oil and Gas Industry

- Emphasizing Efficiency

The oil and gas industry is currently facing a challenge with a lack of highly qualified people. Highly-experienced personnel are leaving the industry, resulting in a reduced number of seasoned staff. This shortage has led to a decrease in efficiency and an increase in costs. Many companies are now turning to VR and AR as the solution for lower costs and increased efficiency, improving their processes over time.

Why The Oil & Gas Industry has Been Slow to Adopt AR/VR

- Risks

In high-risk industries, the safety of employees is paramount, companies require thorough testing of the product before bringing any technology solutions on-site. This testing takes time and money and can sometimes be a drawn-out process, but is necessary to ensure proper safety standards.

Trained professionals need to be on-site to help induct employees, showing them how to use the VR kit effectively if it’s their first time. Once employees have been through an initial on-boarding process, they will be able to complete their VR activities effectively.

- Limited Access

Furthermore, AR/VR applications require a large data bandwidth, which can be difficult to access at oil and gas field sites. Fields are frequently far away and difficult to access, making it difficult to provide adequate connectivity if the VR content requires an internet connection.

However, with the rise of technologies like 5G and SpaceX’s Starlink, data-streaming is gradually becoming more accessible, and as it does, it opens new opportunities for AR/VR use in oil and gas companies.

Additionally, the costs of headsets gets cheaper over time, it helps to improve the relevance and use of the tech.

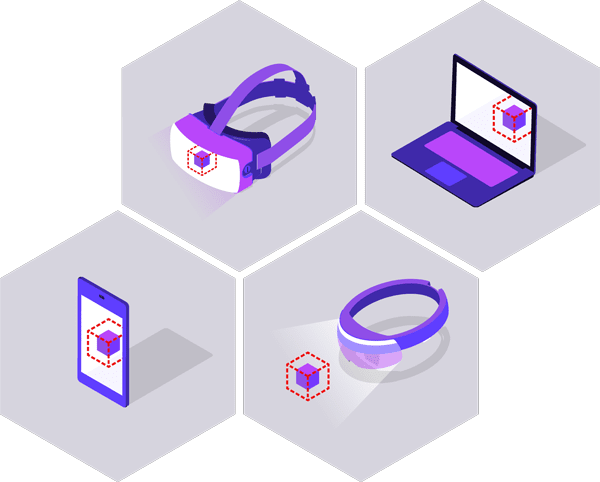

The Difference between AR and VR

So what is the difference between the two? Augmented reality is the process of enhancing a person’s view of the real world by adding digital elements. AR headsets overlay animated objects and graphics onto real scenes. These digital elements can be anything from text to video.

AR has many different use cases but it is particularly useful for Oil & Gas operations, which can be complex and often dangerous. Workers in the field can take advantage of augmented reality displays to show visual indicators or instructions without diverting attention from their surroundings.

By comparison, virtual reality is the process of creating a digital environment that can be experienced through a headset. When workers are in a VR environment, they can experience things that wouldn’t be possible in the real world. This allows employees to explore sites and solutions that otherwise might be inaccessible to them.

For example, workers can walk through a pipeline and inspect it for damage, or they can explore an oil rig to see how it works all while working from a remote location.

Use cases in the Oil & Gas Industry

There are many ways in which AR/VR has been used in oil and gas in the past. Here are a selection of examples which showcase the relevance and impact of the immersive technologies:

- Predictive safety monitoring

For companies in this industry, safety is a top priority. Many hazards may occur at any time, so it’s critical to be able to anticipate safety issues before they arise.

AR/VR can help with this because it allows you to create virtual worlds in which safety risks can be tested out and analysed, giving an accurate prediction of how a safety issue could play out in the real world.

For example, if there is a problem with a piece of equipment, engineers can create a virtual replica of the equipment and test out different scenarios to see how best to fix the issue. This can help to avoid safety problems and save time and money. Not to mention, the benefits of creating thorough emergency responses to handle issues when they do arise.

- Training

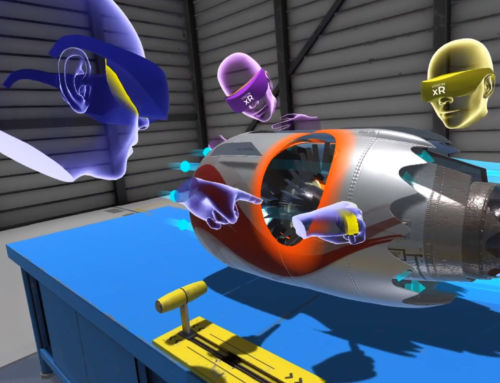

VR and AR can also be extremely helpful for training processes. They can give employees a more realistic experience of what they will be working with, which can help them be better prepared for the job. VR and AR can also help train employees to learn new tasks more quickly and safely.

For example, AR can be used to show employees how to properly connect a pipe, which can help them avoid potential accidents. They also help cut training costs by allowing employees to train from remote locations. This allows for new employees to receive proper training and avoid dangerous situations.

Transforming the Oil and Gas Industry

AR and VR will form the bedrock of the industrial training. This technology allows for workers to be safer and better informed when working on oil & gas fields. They also allow for employees to be trained virtually and be given more hands-on experience in their training, enhancing knowledge retention whilst in a risk-free environment.

While some valid concerns must still be addressed, such as cost and a lack of standards, the industry is slowly but surely making the shift to these new technologies.

If you’re interested in learning more about how virtual reality can benefit your business or would like to try out our VR training software, please don’t hesitate to reach out. We would love to show you a demo of our VisionXR software so you can experience firsthand how this exciting new technology can enhance your teamwork within your company.

This industry has been facing new and unprecedented challenges. To meet the increasing demand, companies are having to do more with less. This means that they are using fewer employees and tighter budgets. How can the industry keep up with these unprecedented times?

To keep up with the pace of the industry, it’s no surprise that oil and gas companies are turning to AR and VR to help create a more efficient workflow. By using immersive technologies to revamp their work processes, oil companies are finding major cost savings that help their businesses soar.

How AR/VR can Benefit the Oil and Gas Industry

- Emphasizing Efficiency

The oil and gas industry is currently facing a challenge with a lack of highly qualified people. Highly-experienced personnel are leaving the industry, resulting in a reduced number of seasoned staff. This shortage has led to a decrease in efficiency and an increase in costs. Many companies are now turning to VR and AR as the solution for lower costs and increased efficiency, improving their processes over time.

Why The Oil & Gas Industry has Been Slow to Adopt AR/VR

- Risks

In high-risk industries, the safety of employees is paramount, companies require thorough testing of the product before bringing any technology solutions on-site. This testing takes time and money and can sometimes be a drawn-out process, but is necessary to ensure proper safety standards.

Trained professionals need to be on-site to help induct employees, showing them how to use the VR kit effectively if it’s their first time. Once employees have been through an initial on-boarding process, they will be able to complete their VR activities effectively.

- Limited Access

Furthermore, AR/VR applications require a large data bandwidth, which can be difficult to access at oil and gas field sites. Fields are frequently far away and difficult to access, making it difficult to provide adequate connectivity if the VR content requires an internet connection.

However, with the rise of technologies like 5G and SpaceX’s Starlink, data-streaming is gradually becoming more accessible, and as it does, it opens new opportunities for AR/VR use in oil and gas companies.

Additionally, the costs of headsets gets cheaper over time, it helps to improve the relevance and use of the tech.

The Difference between AR and VR

So what is the difference between the two? Augmented reality is the process of enhancing a person’s view of the real world by adding digital elements. AR headsets overlay animated objects and graphics onto real scenes. These digital elements can be anything from text to video.

AR has many different use cases but it is particularly useful for Oil & Gas operations, which can be complex and often dangerous. Workers in the field can take advantage of augmented reality displays to show visual indicators or instructions without diverting attention from their surroundings.

By comparison, virtual reality is the process of creating a digital environment that can be experienced through a headset. When workers are in a VR environment, they can experience things that wouldn’t be possible in the real world. This allows employees to explore sites and solutions that otherwise might be inaccessible to them.

For example, workers can walk through a pipeline and inspect it for damage, or they can explore an oil rig to see how it works all while working from a remote location.

Use cases in the Oil & Gas Industry

There are many ways in which AR/VR has been used in oil and gas in the past. Here are a selection of examples which showcase the relevance and impact of the immersive technologies:

- Predictive safety monitoring

For companies in this industry, safety is a top priority. Many hazards may occur at any time, so it’s critical to be able to anticipate safety issues before they arise.

AR/VR can help with this because it allows you to create virtual worlds in which safety risks can be tested out and analysed, giving an accurate prediction of how a safety issue could play out in the real world.

For example, if there is a problem with a piece of equipment, engineers can create a virtual replica of the equipment and test out different scenarios to see how best to fix the issue. This can help to avoid safety problems and save time and money. Not to mention, the benefits of creating thorough emergency responses to handle issues when they do arise.

- Training

VR and AR can also be extremely helpful for training processes. They can give employees a more realistic experience of what they will be working with, which can help them be better prepared for the job. VR and AR can also help train employees to learn new tasks more quickly and safely.

For example, AR can be used to show employees how to properly connect a pipe, which can help them avoid potential accidents. They also help cut training costs by allowing employees to train from remote locations. This allows for new employees to receive proper training and avoid dangerous situations.

Transforming the Oil and Gas Industry

AR and VR will form the bedrock of the industrial training. This technology allows for workers to be safer and better informed when working on oil & gas fields. They also allow for employees to be trained virtually and be given more hands-on experience in their training, enhancing knowledge retention whilst in a risk-free environment.

While some valid concerns must still be addressed, such as cost and a lack of standards, the industry is slowly but surely making the shift to these new technologies.

If you’re interested in learning more about how virtual reality can benefit your business or would like to try out our VR training software, please don’t hesitate to reach out. We would love to show you a demo of our VisionXR software so you can experience firsthand how this exciting new technology can enhance your teamwork within your company.