With the pandemic transforming trends across the world, many industries have turned to technology for greater resilience, flexibility and productivity in the workplace.

For the engineering industry – where collaborative interaction with physical prototypes is a priority – many businesses have turned to VR’s lesser-known relative, augmented reality.

Unlike virtual reality, where you’re transported to a new environment detached from the real world, augmented reality overlays 3D images in your current setting.

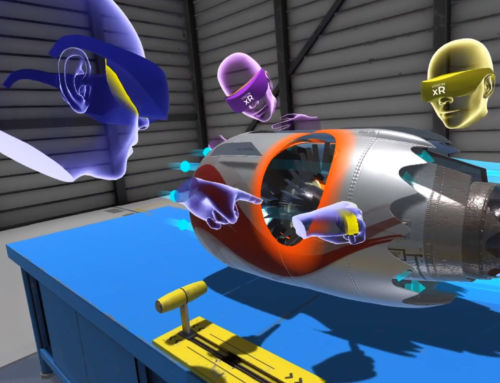

For engineers, it means anyone involved in a project can create, visualise and manipulate 3D CAD prototypes in a collaborative environment from anywhere in the world.

But freedom from the physical factory is just the tip of the iceberg when it comes to the benefits associated with augmented reality. Here’s a complete guide on why it’s become a go-to tool in the world of engineering.

How AR is shaping engineering

Though it’s assumed augmented reality is exclusively used in the design stage, its technology is also implemented in component assembly, support maintenance and subsequent repair procedures.

By overlaying augmented reality to a real-life environment, designers and engineers can make accurate conclusions from 3D prototypes to increase productivity during each stage of a project.

What’s more, by employing immersive technology, it becomes easier to demonstrate spatial concepts that might only be available as a limited 2D illustration.

Not only does this take any guesswork out of a prototype, but it also means product developers are better positioned to identify defects that could potentially cost time and money during production.

However, despite augmented reality’s improvements to the engineering industry, some business owners remain apprehensive about new ways of working.

But with the benefits we’re about to share with you, it’s only a matter of time before augmented reality becomes an industry-standard tool in the engineering industry.

Benefits of using AR in the engineering sector

We’ve already covered how augmented reality can increase efficiency, colleague satisfaction and design accuracy. But here are more benefits available through immersive technology.

Accurate defect detection

Using 3D modeling software, engineers can visualise and interact with every product component, gauging their fit and functionality within an intended environment. It reduces guesswork and possible costly adjustments to designs.

Enhanced professional development

By interacting with prototypes in a hands-on environment, engineers are more likely to comprehend and retain valuable information. The same principle is applied to engineering students who can interact with components without the fear of personal injury or costly errors.

Improved safety standards

Through the interaction of 3D CAD modeling and virtual guidance from industry experts, augmented reality has the potential to reduce the risk of accidents or injuries in the workplace. Handling the production environment through immersive technology means employees feel safer and potentially more valued in the workplace, resulting in greater efficiency and overall productivity.

Examples of brands using AR in engineering

BMW

By linking augmented reality software to their product data management system, BMW can visualise and interact with true-to-scale prototypes before they’re approved for manufacturing. As well as saving time and money through the development process, the inclusion of augmented reality enables designers and engineers to work from remote locations without stepping foot in a factory.

BASF

Using digital twin through Augmented Reality Engineering Space, BASF engineers can visualise planned pipelines on-site to accurately determine whether they will function as intended. What’s more, during the engineering stage, on-site monitoring through augmented reality helps to identify and correct any design faults before they lead to subsequent problems.

The future of AR in engineering

Engineers and designers have long relied on CAD data to plan, develop and produce a range of complex products and machinery – and, to date, it’s been a success. So what’s the need for AR?

Well, the short answer is augmented reality brings data to life. It takes your CAD data and turns it into a 3D model you can visualise, test and manipulate in situ with no guesswork required.

It’s a leap in engineering planning that 2D CAD illustrations and blueprints simply can’t match. And with the global forecast spending for AR and VR expected to reach $72.8 billion by 2024, it’s safe to assume immersive technology is here to stay.

Perhaps the ultimate pull to incorporating AR isn’t the added engagement it brings to the design process, but the comfort of knowing designs are more accurate and less likely to be recalled later down the line.

After all, operating an engineering business is about making profit. And if there’s a technology available proven to limit risk during production, it’s a smart move to join the workplace evolution.

Want to see how augmented reality can help you in the workplace?

Get in touch today for a FREE demo.

With the pandemic transforming trends across the world, many industries have turned to technology for greater resilience, flexibility and productivity in the workplace.

For the engineering industry – where collaborative interaction with physical prototypes is a priority – many businesses have turned to VR’s lesser-known relative, augmented reality.

Unlike virtual reality, where you’re transported to a new environment detached from the real world, augmented reality overlays 3D images in your current setting.

For engineers, it means anyone involved in a project can create, visualise and manipulate 3D CAD prototypes in a collaborative environment from anywhere in the world.

But freedom from the physical factory is just the tip of the iceberg when it comes to the benefits associated with augmented reality. Here’s a complete guide on why it’s become a go-to tool in the world of engineering.

How AR is shaping engineering

Though it’s assumed augmented reality is exclusively used in the design stage, its technology is also implemented in component assembly, support maintenance and subsequent repair procedures.

By overlaying augmented reality to a real-life environment, designers and engineers can make accurate conclusions from 3D prototypes to increase productivity during each stage of a project.

What’s more, by employing immersive technology, it becomes easier to demonstrate spatial concepts that might only be available as a limited 2D illustration.

Not only does this take any guesswork out of a prototype, but it also means product developers are better positioned to identify defects that could potentially cost time and money during production.

However, despite augmented reality’s improvements to the engineering industry, some business owners remain apprehensive about new ways of working.

But with the benefits we’re about to share with you, it’s only a matter of time before augmented reality becomes an industry-standard tool in the engineering industry.

Benefits of using AR in the engineering sector

We’ve already covered how augmented reality can increase efficiency, colleague satisfaction and design accuracy. But here are more benefits available through immersive technology.

Accurate defect detection

Using 3D modeling software, engineers can visualise and interact with every product component, gauging their fit and functionality within an intended environment. It reduces guesswork and possible costly adjustments to designs.

Enhanced professional development

By interacting with prototypes in a hands-on environment, engineers are more likely to comprehend and retain valuable information. The same principle is applied to engineering students who can interact with components without the fear of personal injury or costly errors.

Improved safety standards

Through the interaction of 3D CAD modeling and virtual guidance from industry experts, augmented reality has the potential to reduce the risk of accidents or injuries in the workplace. Handling the production environment through immersive technology means employees feel safer and potentially more valued in the workplace, resulting in greater efficiency and overall productivity.

Examples of brands using AR in engineering

BMW

By linking augmented reality software to their product data management system, BMW can visualise and interact with true-to-scale prototypes before they’re approved for manufacturing. As well as saving time and money through the development process, the inclusion of augmented reality enables designers and engineers to work from remote locations without stepping foot in a factory.

BASF

Using digital twin through Augmented Reality Engineering Space, BASF engineers can visualise planned pipelines on-site to accurately determine whether they will function as intended. What’s more, during the engineering stage, on-site monitoring through augmented reality helps to identify and correct any design faults before they lead to subsequent problems.

The future of AR in engineering

Engineers and designers have long relied on CAD data to plan, develop and produce a range of complex products and machinery – and, to date, it’s been a success. So what’s the need for AR?

Well, the short answer is augmented reality brings data to life. It takes your CAD data and turns it into a 3D model you can visualise, test and manipulate in situ with no guesswork required.

It’s a leap in engineering planning that 2D CAD illustrations and blueprints simply can’t match. And with the global forecast spending for AR and VR expected to reach $72.8 billion by 2024, it’s safe to assume immersive technology is here to stay.

Perhaps the ultimate pull to incorporating AR isn’t the added engagement it brings to the design process, but the comfort of knowing designs are more accurate and less likely to be recalled later down the line.

After all, operating an engineering business is about making profit. And if there’s a technology available proven to limit risk during production, it’s a smart move to join the workplace evolution.