Working at height is the biggest cause of fatalities and major injuries in the workplace. In 2021, the Health and Safety Executive (HSE) reported 29 fatal accidents were caused in the UK from working at height.

Though it’s best to avoid working at height whenever possible, sometimes it’s unavoidable. So here’s our breakdown on how to work at height safely.

What is classed as working at height?

According to the HSE, to ‘work at height’ means to work in any place where, if there were no precautions in place, a person could fall a distance liable to cause personal injury.

Whether working off a ladder, on a fragile roof, near a ledge or even at ground level near a well or opening, each of these scenarios can cause major injury or even fatalities.

In general industry, fall protection is required by Occupational Safety and Health Administration (OSHA) for any height change of four feet or more. You might think that isn’t much of a fall, but it’s enough to cause serious harm.

Examples of hazards when working at height

There are many work-related roles and responsibilities which involve working from height. Whether on a roof, elevated structures, loading platforms or even on top of vehicles or trailers, risk assessments must be put in place for each and every scenario.

Here are some typical examples of hazards when working at height:

Misuse of ladders

Falling off a ladder is one of the most common causes of injuries and fatalities. Whenever you’re working off a ladder, check it is set up correctly and conforms to the appropriate height, size and condition.

As initial guidance, those working from ladders should follow the manufacturer’s instructions and avoid over-reaching, carrying heavy objects or working in adverse weather conditions.

Faulty protective equipment

To keep your employees as safe as possible when working from height, it’s essential to regularly check all safety and protective equipment required for each project.

As a priority, fall prevention systems including guardrails and carabiners should be tested in accordance with manufacturer guidance, as well as any lanyards, harnesses and other personal protective equipment (PPE).

Insufficient risk assessments

To assess every potential hazard from working at height, the HSE share control measures, which include these simple steps:

- Avoid working at height where it’s reasonably practical to do so

- Where work at height cannot be easily avoided, prevent falls using an existing place of work that is already safe or the right type of equipment

- Minimise the distance and consequences of a fall by using the right type of equipment where the risk cannot be eliminated

Following these simple steps to put in place a watertight risk assessment will help to keep you and your employees safe when working at height.

Lack of familiarity and experience

Even with all the necessary risk assessments and protection in place, an employee with little experience working at height could be at higher risk of suffering an injury or fatality.

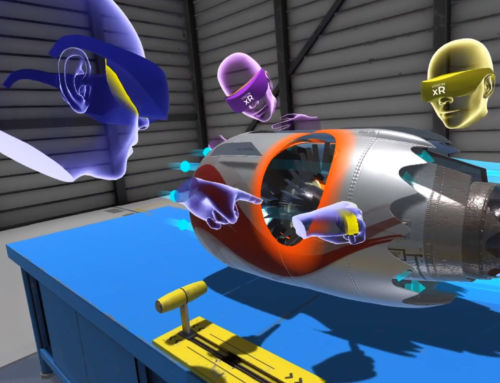

On-the-job supervision and training can help to build knowledge and confidence, but if you want to limit 100% of hazards while your employees are still learning the ropes, perhaps you should consider VISIONxR? Get in touch to book a demo.

Poorly erected scaffolding and roofs

Falling from failed scaffolding or through fragile roofs is a common way workers are injured when working at height.

As well as carrying out comprehensive safety checks prior to any work being completed, it is also necessary to continue with checks of the worksite throughout the duration of the job.

Tips on how to work at height safely

Invest in PPE

As part of your risk assessment, you should identify what type of PPE is required when working at height. Standard types of equipment available to workers include:

- harnesses

- shock-absorbing lanyards

- pole straps

- connectors

- carabiners

- catch platforms

- safety nets

Of course, using PPE should be the last resort to protect against risks. Here’s the hierarchy of controls shared by HSE:

- Elimination – physically remove the hazard

- Substitution – replace the hazard

- Engineering controls – isolate people from the hazard

- Administrative controls – change the way people work

- PPE – protect the worker with equipment

Regularly inspect safety equipment

Checking your equipment for deterioration defects will limit the chance of any incidents in the workplace.

From quick visual checks to more thorough inspections, putting a schedule in place to regularly monitor the condition of all safety equipment will help to prevent accidents.

If you identify any equipment with any sort of defect, it should not be used. All used equipment from hire companies should also be accompanied by physical evidence of a previous safety inspection.

Follow ladder regulations

When it comes to working at height, ladders are permitted if the work is deemed low risk and only required for a short duration.

As well as checking your ladders are in a safe working condition, training should also be given to users, including:

- how to assess the risks of using a ladder for a particular task

- when it is right to use a ladder (and when it is not)

- which type of ladder to use and how to use it

Before using a ladder, make sure it is the right equipment for the task. Cutting costs of erecting proper safety barriers and towers could potentially cause major injury and loss of life.

Implement a fall protection system

Working at height can quite often be a lonely job. And in the event of an accident happening, an injured worker might not receive help or treatment for a considerable amount of time.

But with a fall protection system, an alarm is automatically raised should a fall from height or a period of non-movement be detected in the workplace.

Implement working-at-height training

To keep your team safe when working at height, they need to be properly educated and trained in every potential risk and hazard in the workplace.

Formal training and certification are available through providers such as CSCS, PASMA and IPAF. Following initial training, refresher training should be completed within recommended time frames.

As with any task we conduct on a daily basis, complacency may find its way through the cracks. And though this might be forgivable in certain roles, taking your eye off the ball when working at height can have far more serious consequences.

The importance of training for working at height

Failing to provide adequate working-from-height training can lead to major injuries and potential fatalities. Under the Work at Height Regulations 2005, employers are responsible for limiting risks when working at height.

Not only does this include assessing every risk in the workplace, but also ensuring staff are equipped with the necessary skills, knowledge and experience to safely complete tasks when working at height.

Training staff on-site is an option but it still comes with its risks. So if you want to help employees build their competency in a safe and secure environment, it’s worth considering working at height training using VR.

Using VR for training gives users life-like scenarios of potential risks and hazards when working at height. No matter the job, occupation or industry, bespoke programmes can be implemented to accelerate learning in a safe and secure environment.

If you’d like to learn more about how to work at height safely using VR training, feel free to get in touch to book a demo.

Working at height is the biggest cause of fatalities and major injuries in the workplace. In 2021, the Health and Safety Executive (HSE) reported 29 fatal accidents were caused in the UK from working at height.

Though it’s best to avoid working at height whenever possible, sometimes it’s unavoidable. So here’s our breakdown on how to work at height safely.

What is classed as working at height?

According to the HSE, to ‘work at height’ means to work in any place where, if there were no precautions in place, a person could fall a distance liable to cause personal injury.

Whether working off a ladder, on a fragile roof, near a ledge or even at ground level near a well or opening, each of these scenarios can cause major injury or even fatalities.

In general industry, fall protection is required by Occupational Safety and Health Administration (OSHA) for any height change of four feet or more. You might think that isn’t much of a fall, but it’s enough to cause serious harm.

Examples of hazards when working at height

There are many work-related roles and responsibilities which involve working from height. Whether on a roof, elevated structures, loading platforms or even on top of vehicles or trailers, risk assessments must be put in place for each and every scenario.

Here are some typical examples of hazards when working at height:

Misuse of ladders

Falling off a ladder is one of the most common causes of injuries and fatalities. Whenever you’re working off a ladder, check it is set up correctly and conforms to the appropriate height, size and condition.

As initial guidance, those working from ladders should follow the manufacturer’s instructions and avoid over-reaching, carrying heavy objects or working in adverse weather conditions.

Faulty protective equipment

To keep your employees as safe as possible when working from height, it’s essential to regularly check all safety and protective equipment required for each project.

As a priority, fall prevention systems including guardrails and carabiners should be tested in accordance with manufacturer guidance, as well as any lanyards, harnesses and other personal protective equipment (PPE).

Insufficient risk assessments

To assess every potential hazard from working at height, the HSE share control measures, which include these simple steps:

- Avoid working at height where it’s reasonably practical to do so

- Where work at height cannot be easily avoided, prevent falls using an existing place of work that is already safe or the right type of equipment

- Minimise the distance and consequences of a fall by using the right type of equipment where the risk cannot be eliminated

Following these simple steps to put in place a watertight risk assessment will help to keep you and your employees safe when working at height.

Lack of familiarity and experience

Even with all the necessary risk assessments and protection in place, an employee with little experience working at height could be at higher risk of suffering an injury or fatality.

On-the-job supervision and training can help to build knowledge and confidence, but if you want to limit 100% of hazards while your employees are still learning the ropes, perhaps you should consider VISIONxR? Get in touch to book a demo.

Poorly erected scaffolding and roofs

Falling from failed scaffolding or through fragile roofs is a common way workers are injured when working at height.

As well as carrying out comprehensive safety checks prior to any work being completed, it is also necessary to continue with checks of the worksite throughout the duration of the job.

Tips on how to work at height safely

Invest in PPE

As part of your risk assessment, you should identify what type of PPE is required when working at height. Standard types of equipment available to workers include:

- harnesses

- shock-absorbing lanyards

- pole straps

- connectors

- carabiners

- catch platforms

- safety nets

Of course, using PPE should be the last resort to protect against risks. Here’s the hierarchy of controls shared by HSE:

- Elimination – physically remove the hazard

- Substitution – replace the hazard

- Engineering controls – isolate people from the hazard

- Administrative controls – change the way people work

- PPE – protect the worker with equipment

Regularly inspect safety equipment

Checking your equipment for deterioration defects will limit the chance of any incidents in the workplace.

From quick visual checks to more thorough inspections, putting a schedule in place to regularly monitor the condition of all safety equipment will help to prevent accidents.

If you identify any equipment with any sort of defect, it should not be used. All used equipment from hire companies should also be accompanied by physical evidence of a previous safety inspection.

Follow ladder regulations

When it comes to working at height, ladders are permitted if the work is deemed low risk and only required for a short duration.

As well as checking your ladders are in a safe working condition, training should also be given to users, including:

- how to assess the risks of using a ladder for a particular task

- when it is right to use a ladder (and when it is not)

- which type of ladder to use and how to use it

Before using a ladder, make sure it is the right equipment for the task. Cutting costs of erecting proper safety barriers and towers could potentially cause major injury and loss of life.

Implement a fall protection system

Working at height can quite often be a lonely job. And in the event of an accident happening, an injured worker might not receive help or treatment for a considerable amount of time.

But with a fall protection system, an alarm is automatically raised should a fall from height or a period of non-movement be detected in the workplace.

Implement working-at-height training

To keep your team safe when working at height, they need to be properly educated and trained in every potential risk and hazard in the workplace.

Formal training and certification are available through providers such as CSCS, PASMA and IPAF. Following initial training, refresher training should be completed within recommended time frames.

As with any task we conduct on a daily basis, complacency may find its way through the cracks. And though this might be forgivable in certain roles, taking your eye off the ball when working at height can have far more serious consequences.

The importance of training for working at height

Failing to provide adequate working-from-height training can lead to major injuries and potential fatalities. Under the Work at Height Regulations 2005, employers are responsible for limiting risks when working at height.

Not only does this include assessing every risk in the workplace, but also ensuring staff are equipped with the necessary skills, knowledge and experience to safely complete tasks when working at height.

Training staff on-site is an option but it still comes with its risks. So if you want to help employees build their competency in a safe and secure environment, it’s worth considering working at height training using VR.

Using VR for training gives users life-like scenarios of potential risks and hazards when working at height. No matter the job, occupation or industry, bespoke programmes can be implemented to accelerate learning in a safe and secure environment.

If you’d like to learn more about how to work at height safely using VR training, feel free to get in touch to book a demo.