Key Takeaways

The importance of health and safety in the petroleum industry

In a field with heavy machinery, flammable chemicals and unforgiving natural elements, it’s no wonder the oil and gas industry has a fatality rate seven times higher than any other in the world.

Often carried out in remote locations, those who work in the oil and gas industry need to know the risks of an inherently dangerous environment and what to do to mitigate the risk of injury (or worse).

It’s the reason oil and gas industry leaders are pursuing new ways to improve safety standards. Not only to protect employees from harm, but also to limit the potential risk of financial failure in the event of an incident.

And although the industry has made recent efforts to improve safety standards, workers are still at risk of common hazards, which most commonly involve being struck by equipment, explosions, fires, falls and chemical exposure.

But how can industry leaders improve employee awareness of risks and hazards while guaranteeing their safety during the learning process? Well, one way could be classroom-based theory, but if you really want a training programme that works, we suggest virtual reality (VR).

Examples of dangerous jobs in the oil and gas industry

Among the multitude of dangerous jobs in the oil and gas industry, here are the roles that involve the highest risk.

Derrick hands

As well as supervising the maintenance and repairs of equipment malfunction, derrick hands also monitor, insert and extract drilling machinery. The role also involves working at heights while navigating potential adverse conditions in remote locations.

Oilfield drivers

Although driver roles in the oil and gas industry are considered well paid, under the Federal Motor Carrier Safety Administration (FMCSA), the waiting time is counted as ‘off duty’.

It means drivers often work long shifts to make up for the loss of pay, causing a higher rate of accidents directly related to fatigue.

Roustabouts

Roustabout roles generally don’t require any handling of complex machinery. Instead, the role involves general labour, which includes physical tasks often performed in extreme climates with excessive cold or heat. You might say roustabouts are the frontline workers of the oil and gas industry.

Using VR for oil and gas safety training

When it comes to the oil and gas industry, a well-trained team aware of potential risks and hazards can be the difference between a successful project completion or catastrophic failure.

While many companies make huge efforts to protect employees from ever-present risks, there’s a growing awareness more must be done to mitigate injury and fatalities.

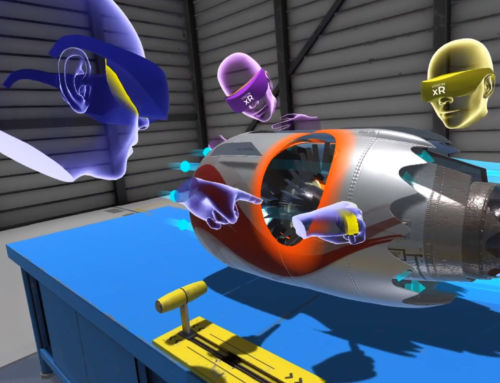

For this reason, industry leaders now implement VR into their training procedures, providing a platform for workers to be exposed to real-world scenarios without the real-world risks.

This might include mock drills, operating complex machinery or responding to an emergency such as oil spills, fires or gas leaks. All of which are conducted in a safe environment where users are educated on how to appropriately respond if such events ever occur.

There is an argument that similar training could be conducted in a traditional classroom setting, but, in doing so, employers remove the sensory experience that comes with first-person VR modules. Why tell employees what to expect when you can show them?

What’s more, VR training modules can be easily modified to fit the exact needs of any oil and gas company. They also have capacity to involve multiple participants in any given scenario, which develops communication skills vital for any well-functioning team.

How VR is transforming the oil and gas industry today

It’s unarguable VR safety training has become more prominent in the oil and gas industry. With more and more industry leaders realising its string of benefits, its presence continues to grow globally across the sector.

Perhaps the main reason for its integration is down to the ease of accessibility for all workers. Because unlike the arduous task of travelling to dedicated learning centres, employees can enter a training module instantly, simply by wearing a headset.

In doing so, workers enjoy a totally immersive and autonomous learning environment which – as multiple studies have proven – leads to higher engagement as well as stronger retainment of knowledge.

For employers, it means you save time and money on traditional training methods, while ensuring employees are better prepared to anticipate and deal with any health and safety-related events.

If you’d like to learn more about using VR for safety training in the oil and gas industry, fill in our quick and easy contact form and we’ll get straight back to you.

Key Takeaways

The importance of health and safety in the petroleum industry

In a field with heavy machinery, flammable chemicals and unforgiving natural elements, it’s no wonder the oil and gas industry has a fatality rate seven times higher than any other in the world.

Often carried out in remote locations, those who work in the oil and gas industry need to know the risks of an inherently dangerous environment and what to do to mitigate the risk of injury (or worse).

It’s the reason oil and gas industry leaders are pursuing new ways to improve safety standards. Not only to protect employees from harm, but also to limit the potential risk of financial failure in the event of an incident.

And although the industry has made recent efforts to improve safety standards, workers are still at risk of common hazards, which most commonly involve being struck by equipment, explosions, fires, falls and chemical exposure.

But how can industry leaders improve employee awareness of risks and hazards while guaranteeing their safety during the learning process? Well, one way could be classroom-based theory, but if you really want a training programme that works, we suggest virtual reality (VR).

Examples of dangerous jobs in the oil and gas industry

Among the multitude of dangerous jobs in the oil and gas industry, here are the roles that involve the highest risk.

Derrick hands

As well as supervising the maintenance and repairs of equipment malfunction, derrick hands also monitor, insert and extract drilling machinery. The role also involves working at heights while navigating potential adverse conditions in remote locations.

Oilfield drivers

Although driver roles in the oil and gas industry are considered well paid, under the Federal Motor Carrier Safety Administration (FMCSA), the waiting time is counted as ‘off duty’.

It means drivers often work long shifts to make up for the loss of pay, causing a higher rate of accidents directly related to fatigue.

Roustabouts

Roustabout roles generally don’t require any handling of complex machinery. Instead, the role involves general labour, which includes physical tasks often performed in extreme climates with excessive cold or heat. You might say roustabouts are the frontline workers of the oil and gas industry.

Using VR for oil and gas safety training

When it comes to the oil and gas industry, a well-trained team aware of potential risks and hazards can be the difference between a successful project completion or catastrophic failure.

While many companies make huge efforts to protect employees from ever-present risks, there’s a growing awareness more must be done to mitigate injury and fatalities.

For this reason, industry leaders now implement VR into their training procedures, providing a platform for workers to be exposed to real-world scenarios without the real-world risks.

This might include mock drills, operating complex machinery or responding to an emergency such as oil spills, fires or gas leaks. All of which are conducted in a safe environment where users are educated on how to appropriately respond if such events ever occur.

There is an argument that similar training could be conducted in a traditional classroom setting, but, in doing so, employers remove the sensory experience that comes with first-person VR modules. Why tell employees what to expect when you can show them?

What’s more, VR training modules can be easily modified to fit the exact needs of any oil and gas company. They also have capacity to involve multiple participants in any given scenario, which develops communication skills vital for any well-functioning team.

How VR is transforming the oil and gas industry today

It’s unarguable VR safety training has become more prominent in the oil and gas industry. With more and more industry leaders realising its string of benefits, its presence continues to grow globally across the sector.

Perhaps the main reason for its integration is down to the ease of accessibility for all workers. Because unlike the arduous task of travelling to dedicated learning centres, employees can enter a training module instantly, simply by wearing a headset.

In doing so, workers enjoy a totally immersive and autonomous learning environment which – as multiple studies have proven – leads to higher engagement as well as stronger retainment of knowledge.

For employers, it means you save time and money on traditional training methods, while ensuring employees are better prepared to anticipate and deal with any health and safety-related events.

If you’d like to learn more about using VR for safety training in the oil and gas industry, fill in our quick and easy contact form and we’ll get straight back to you.