No matter how cautious you may be, working in a high risk environment will always be fraught with danger.

Whether it’s operating machinery, performing surgery or transporting heavy cargo, even the most thorough of risk assessments is no guarantee you’re safe at work.

In fact, according to a recent Labour Force Survey, 441,000 non-fatal injuries were sustained in the workplace last year, with 142 workers losing their life.

So what’s the answer? How can workers be better prepared to deal with the challenges of a high-risk environment without all the risk?

The answer is virtual reality (VR).

Incorporated into any training programme, VR technology provides a safe way to perfect your craft in a fully immersive and risk-free environment.

From mechanical workshops to the surgery table, you’re instantly transported to a real-life workplace, navigating on-the-job problems and scenarios as if you were in a high-risk environment.

What is a high-risk environment?

Simply put, a high-risk environment is anywhere that presents a risk to wellbeing. It could be operating agricultural machinery, working at height or installing and repairing electrical power lines.

And despite the necessary health and safety plans, risk assessments and safety precautions prescribed to each environment, there’s still the risk of injury and harm in the event of the unexpected.

However, with the introduction of VR training programmes, each of these scenarios (and hundreds more) can be simulated to help trainees better understand the dangers of their working environment – all without risk to wellbeing.

Types of jobs exposed to a high-risk environment

There’s an exhaustive list of high-risk environments in the UK, affirmed by the diverse range of industries that incorporate VR into each training programme, including:

-

Healthcare

Trainee doctors can experience 360-degree surgical situations in a risk-free environment, using sensors and controls to practise surgical procedures with real-time feedback.

-

Aviation

Simulated flight gives trainee pilots the experience of operating an aircraft through various events, procedures and scenarios.

They can practise each program as many times as required, building confidence and experience without setting foot inside a real plane.

-

Construction

Those pursuing a career in construction can learn to detect hazards, operate a forklift, assemble scaffolding and much more. All through the immersive experience of a VR headset.

-

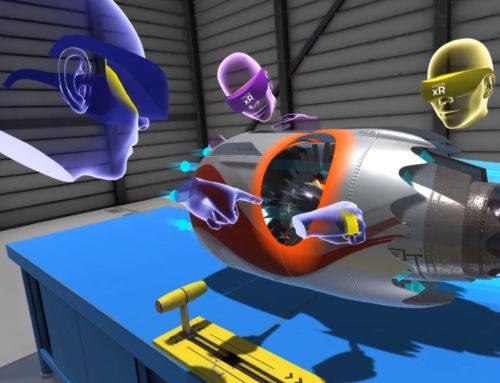

Mechanics

Trainee mechanics can achieve a holistic understanding of machinery by interrogating the inner workings and purpose of any component. They can also troubleshoot potential mechanical problems without the worry of causing costly mistakes to the business.

Of course, we could go on with hundreds of industry-specific examples, but the advantages are clear: VR training is the immersive, innovative and sensible alternative to any type of training conducted in a high-risk environment.

Challenges of training in a high-risk environment

Although training in a high-risk environment provides on-the-job experience, it comes at a price in the form of possible injury or fatality.

Take the construction industry, for example. Building sites are busy environments with multiple trades, materials and heavy machinery in constant use. Place an inexperienced employee in such environments and suddenly you have a recipe for potential disaster. A manufacturing plant is a similar story. Busy workers, heavy machinery and fast-moving production cycles are not the ideal training environment you’d envisage for any new employee.

And that’s not the only problem facing a business that conducts training in high-risk environments. There’s also the impact on productivity. Take, for example, a cargo-handling business. Training staff to load and discharge, operate material-handling equipment and correctly store cargo all takes time, money and space.

It’s why more and more business owners are replacing in-person training with its VR counterpart. It has too many advantages to ignore.

How VR technology can help

By integrating VR technology in training programmes, employees can apply theory to a replica practical setting, providing a springboard to accelerate knowledge and challenge understanding – all in one place.

As well as being completely risk-free, VR gives learners the first-person autonomy to better understand the requirements of their role. Something they’d never experience through a didactic slideshow presentation, for sure.

And if learners make a technical mistake in VR, costs are not incurred in the real world. Instead, they can quickly seek assistance (virtual or otherwise), correct errors and reflect on their experience to quickly develop knowledge, skills and understanding.

In fact, according to a report released by PwC, subjects typically learn up to four times faster through VR training. This is partly due to its immersive qualities, but also owing to the fact it can be accessed anytime, any place and experienced as many times as required.

Benefits of VR technology

1. Safe environment

From handling hazardous equipment to transporting heavy cargo, you can train in the confidence you and your co-workers are completely safe.

2. Improves learning

Giving subjects a platform for unlimited learning means they can explore the ins and outs of tasks and scenarios as many times as they need to, completely risk-free.

3. Reduces costs

Although the initial investment cost of VR hardware, there’s potential for huge savings to future courses and training fees.

4. Team collaboration

VR can create collaborative training environments and experiences to improve teamwork and workflow within any organisation.

5. Environmentally friendly

Bringing colleagues together in a single learning environment – regardless of where they are in the world – prevents unnecessary emissions caused by commuting.

To conclude

Virtual reality offers a safe, immersive and innovative way for your employees to learn outside the parameters of a high-risk environment.

Whether you work in construction, hospitality, engineering or perhaps a niche industry, virtual learning creates a safe and productive workplace for you and your team to flourish together.

Want to give your employees high-risk environment training without all the risk?

Contact us today!

No matter how cautious you may be, working in a high risk environment will always be fraught with danger.

Whether it’s operating machinery, performing surgery or transporting heavy cargo, even the most thorough of risk assessments is no guarantee you’re safe at work.

In fact, according to a recent Labour Force Survey, 441,000 non-fatal injuries were sustained in the workplace last year, with 142 workers losing their life.

So what’s the answer? How can workers be better prepared to deal with the challenges of a high-risk environment without all the risk?

The answer is virtual reality (VR).

Incorporated into any training programme, VR technology provides a safe way to perfect your craft in a fully immersive and risk-free environment.

From mechanical workshops to the surgery table, you’re instantly transported to a real-life workplace, navigating on-the-job problems and scenarios as if you were in a high-risk environment.

What is a high-risk environment?

Simply put, a high-risk environment is anywhere that presents a risk to wellbeing. It could be operating agricultural machinery, working at height or installing and repairing electrical power lines.

And despite the necessary health and safety plans, risk assessments and safety precautions prescribed to each environment, there’s still the risk of injury and harm in the event of the unexpected.

However, with the introduction of VR training programmes, each of these scenarios (and hundreds more) can be simulated to help trainees better understand the dangers of their working environment – all without risk to wellbeing.

Types of jobs exposed to a high-risk environment

There’s an exhaustive list of high-risk environments in the UK, affirmed by the diverse range of industries that incorporate VR into each training programme, including:

-

Healthcare

Trainee doctors can experience 360-degree surgical situations in a risk-free environment, using sensors and controls to practise surgical procedures with real-time feedback.

-

Aviation

Simulated flight gives trainee pilots the experience of operating an aircraft through various events, procedures and scenarios.

They can practise each program as many times as required, building confidence and experience without setting foot inside a real plane.

-

Construction

Those pursuing a career in construction can learn to detect hazards, operate a forklift, assemble scaffolding and much more. All through the immersive experience of a VR headset.

-

Mechanics

Trainee mechanics can achieve a holistic understanding of machinery by interrogating the inner workings and purpose of any component. They can also troubleshoot potential mechanical problems without the worry of causing costly mistakes to the business.

Of course, we could go on with hundreds of industry-specific examples, but the advantages are clear: VR training is the immersive, innovative and sensible alternative to any type of training conducted in a high-risk environment.

Challenges of training in a high-risk environment

Although training in a high-risk environment provides on-the-job experience, it comes at a price in the form of possible injury or fatality.

Take the construction industry, for example. Building sites are busy environments with multiple trades, materials and heavy machinery in constant use. Place an inexperienced employee in such environments and suddenly you have a recipe for potential disaster. A manufacturing plant is a similar story. Busy workers, heavy machinery and fast-moving production cycles are not the ideal training environment you’d envisage for any new employee.

And that’s not the only problem facing a business that conducts training in high-risk environments. There’s also the impact on productivity. Take, for example, a cargo-handling business. Training staff to load and discharge, operate material-handling equipment and correctly store cargo all takes time, money and space.

It’s why more and more business owners are replacing in-person training with its VR counterpart. It has too many advantages to ignore.

How VR technology can help

By integrating VR technology in training programmes, employees can apply theory to a replica practical setting, providing a springboard to accelerate knowledge and challenge understanding – all in one place.

As well as being completely risk-free, VR gives learners the first-person autonomy to better understand the requirements of their role. Something they’d never experience through a didactic slideshow presentation, for sure.

And if learners make a technical mistake in VR, costs are not incurred in the real world. Instead, they can quickly seek assistance (virtual or otherwise), correct errors and reflect on their experience to quickly develop knowledge, skills and understanding.

In fact, according to a report released by PwC, subjects typically learn up to four times faster through VR training. This is partly due to its immersive qualities, but also owing to the fact it can be accessed anytime, any place and experienced as many times as required.

Benefits of VR technology

1. Safe environment

From handling hazardous equipment to transporting heavy cargo, you can train in the confidence you and your co-workers are completely safe.

2. Improves learning

Giving subjects a platform for unlimited learning means they can explore the ins and outs of tasks and scenarios as many times as they need to, completely risk-free.

3. Reduces costs

Although the initial investment cost of VR hardware, there’s potential for huge savings to future courses and training fees.

4. Team collaboration

VR can create collaborative training environments and experiences to improve teamwork and workflow within any organisation.

5. Environmentally friendly

Bringing colleagues together in a single learning environment – regardless of where they are in the world – prevents unnecessary emissions caused by commuting.

To conclude

Virtual reality offers a safe, immersive and innovative way for your employees to learn outside the parameters of a high-risk environment.

Whether you work in construction, hospitality, engineering or perhaps a niche industry, virtual learning creates a safe and productive workplace for you and your team to flourish together.